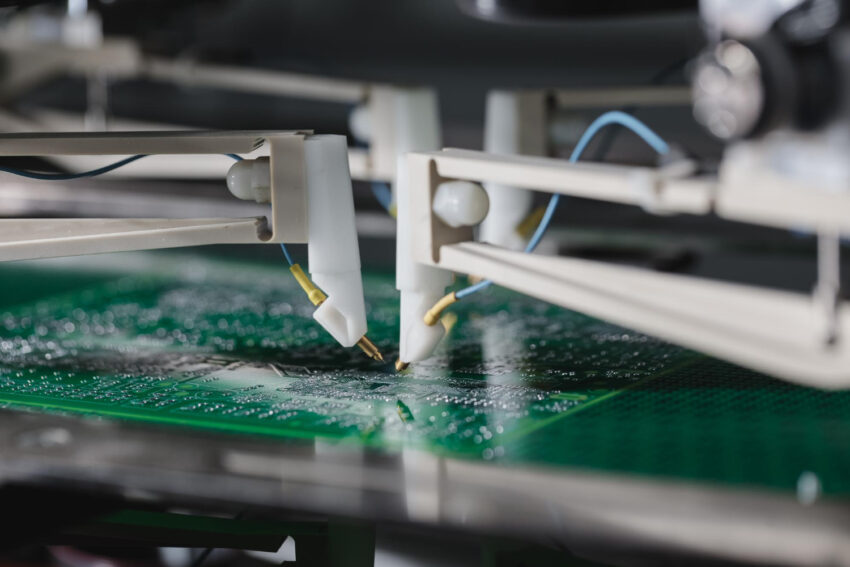

Outsourcing electronic device production to the providers of electronics manufacturing services (EMS) has become a common practice for a number of advantages Original Equipment Manufacturers (OEMs) can enjoy. The most essential benefits offered by effective collaboration with a contract electronics manufacturing provider are discussed in this article.

Significant savings on investment with electronics manufacturing services

One of the most essential benefits OEMs can count on when collaborating with an EMS provider is the possibility of launching production without the need of investment. A qualified electronics manufacturing provider, for instance, Assel with an over 40-year experience on the market, has already established the necessary infrastructure and environment for manufacturing, quality control, and packaging.

While such co-operation obviously minimizes a need to purchase equipment or property and set manufacturing technology for any OEMs, it is a real saviour for companies looking for a low-volume and high-mix production that would otherwise be rather costly.

Leveraging proficient workforce and improving productivity

Of course, contract electronics manufacturing comes with skilled and experienced specialists who have mastered the existing technology for electronics production and are keeping up with the evolution of available solutions. Not only does it mean an original equipment manufacturer does not have to invest one’s effort in organizing and maintaining the production process but one can also count on receiving goods of stable quality and have a clear understanding of manufacturing costs.

Some contract electronics manufacturing providers such as Assel also offer a certain level of flexibility for readjusting an already existing manufacturing process to new requirements, for example, when an OEM needs to increase the batch.

Effective supply chain and inventory management

Although device manufacturing is the major concern of many OEMs looking for an EMS provider, it is crucial to note they can also get complex support for the supply chain and inventory management which are essential for production efficiency.

These components of project realization can affect the costs of electronic device manufacturing, the quality of the final products as well as their delivery. The latter one, if not happened on time, can cause disruptions in launching the product, thus, affecting the financial condition of the OEM company and reducing its prospects for success in the market in the future.

Conclusions: electronics manufacturing provider as key to your success

Electronics manufacturing services allow OEMs to focus entirely on the process of designing their products and their further promotion on the market leaving the responsible task of manufacturing to expert providers such as Poland-based Assel. To learn more about the extensive offer of Assel for electronic device assembly, visit asselems.com.

Tech World Times (TWT), a global collective focusing on the latest tech news and trends in blockchain, Fintech, Development & Testing, AI and Startups. If you are looking for the guest post then contact at techworldtimes@gmail.com